In general, two different coating processes exist:

1. Coil coating

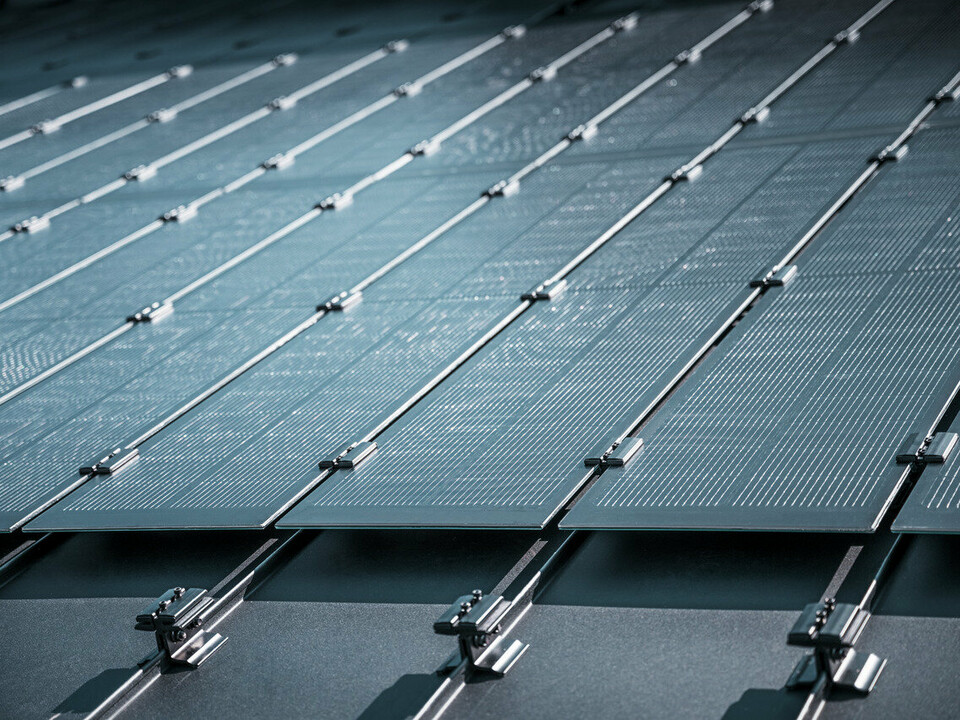

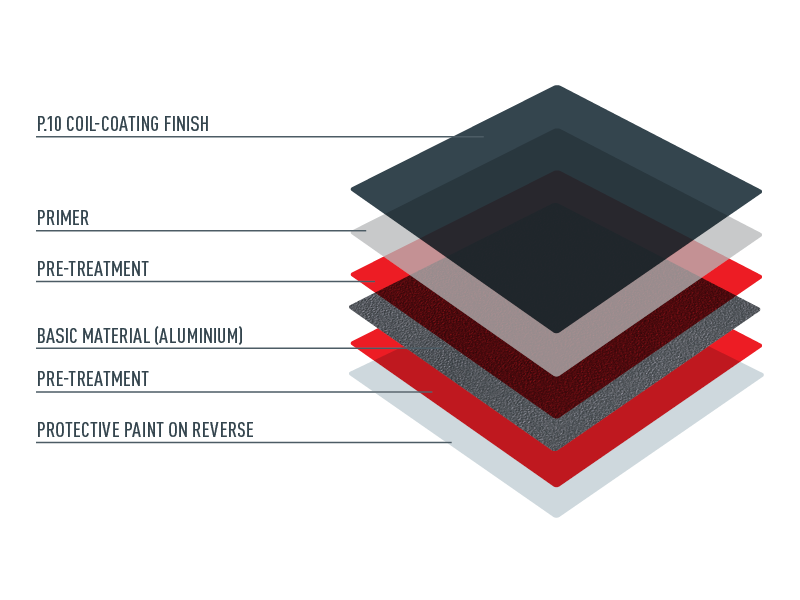

PREFA strips undergo surface treatment in a coil coating process in accordance with the ECCA (European Coil Coating Association). In the process, the strips go through up to 20 processing steps. After pre-treatment, primer is applied to both sides, and cured.

With a continuous temperature resistance of –30 °C to +80 °C, the product complies with the requirements of outside architecture. The coating layer is malleable and protected against general chemicals and weather conditions.

We use four different paint qualities:

- polyester

- PP99 (polyamide / polyurethane)

- PVDF 80/20 (polyvinylidene fluoride)

- P.10

Comparison of polyester and PP99

The difference between polyester and PP99 coatings lies in their different reactions to external weather conditions and UV rays. Long-term tests have shown that the gloss level of the polyester coating is less resistant than the PP99 coating. The polyester coating is also less resistant to chalking than the PP99 coating.

Comparison of PP99 and PVDF 80/20

The quality of the PP99 coating is broadly similar to that of the PVDF 80/20 coating. Long-term tests have shown that the PP99 coating in special shades (such as red, orange and yellow) is not as resistant to chalking as the PVDF 80/20 coating. However, the PP99 coating has high scratch resistance (an advantage during installation).

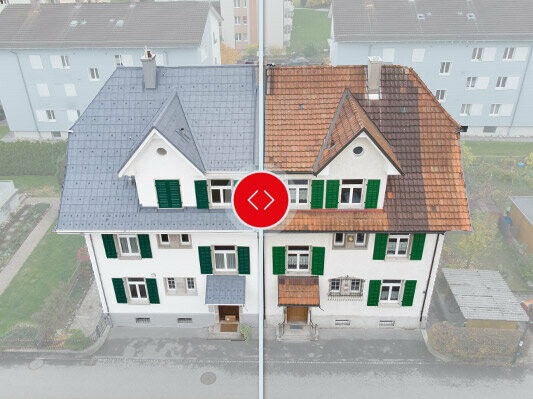

Comparison of P.10 and other materials

Since 2010, the P.10 surface finish has produced a coating quality that provides countless minuscule reflections and colour stability through a special fold structure in the finish that only becomes visible under a microscope. In direct sunlight, the matte surface of the P.10 finish has an elegant appearance. The high-quality surface finish on PREFA products is malleable and is able to withstand temperature fluctuations and weathering.

2. Powder coatinig

Unlike coil coating, powder coating involves coating each individual component. The pretreated parts are transported on a chain conveyor in our fully-automated coating lines. They pass through powder-coating cabins where the powder is applied by automatic guns, before being cured in a furnace at approx. 180 °C. The layer thickness on powder-coated parts is approx. 80 µm. Subsequent shaping of the powder-coated parts is only possible to a limited extent. Powder-coating is an extremely environmentally-friendly method as no solvents are used and any residual powder is circulated back into the powder-coating cycle. With this process, it is possible to powder-coat products with all RAL, NCS and Pantone shades and all other special colours. With PREFA, the scope for colour design is practically unlimited!

3. P.10 Colour-fast surface

With PREFA P.10, we have developed a colour-resistant surface that meets even the highest quality standards. The PREFA P.10 surface coating is the ideal complement for many PREFA products. The result is a material that withstands external influences and stresses and at the same time is incredibly light and stable, offering a wide range of planning and design possibilities.