The whole truth about aluminium

Architecture, technology and even food packaging — aluminium is used in the most diverse sectors. However, the preconceptions about this material are as varied as its possible uses. So we’d like to take this opportunity to clear up the main misunderstandings and dispel the preconceptions once and for all:

Preconception no. 1: “Aluminium is susceptible to corrosion and so gets rusty.” — Nothing of the sort!

If we can put it this way: aluminium reacts in a really smart way. It protects itself from corrosion by reacting with the oxygen in the air to form a natural oxide layer. This layer coats the material like a protective shield, protecting it from environmental influences. Therefore, unlike iron, aluminium does not rust, but oxidizes. If this oxide layer is scratched away, a new surface immediately forms again. In addition, aluminium oxide is almost the same colour as the aluminium itself, and is therefore not noticeable.

Preconception no. 2: “Aluminium is prone to lightning strikes.” — Quite the contrary!

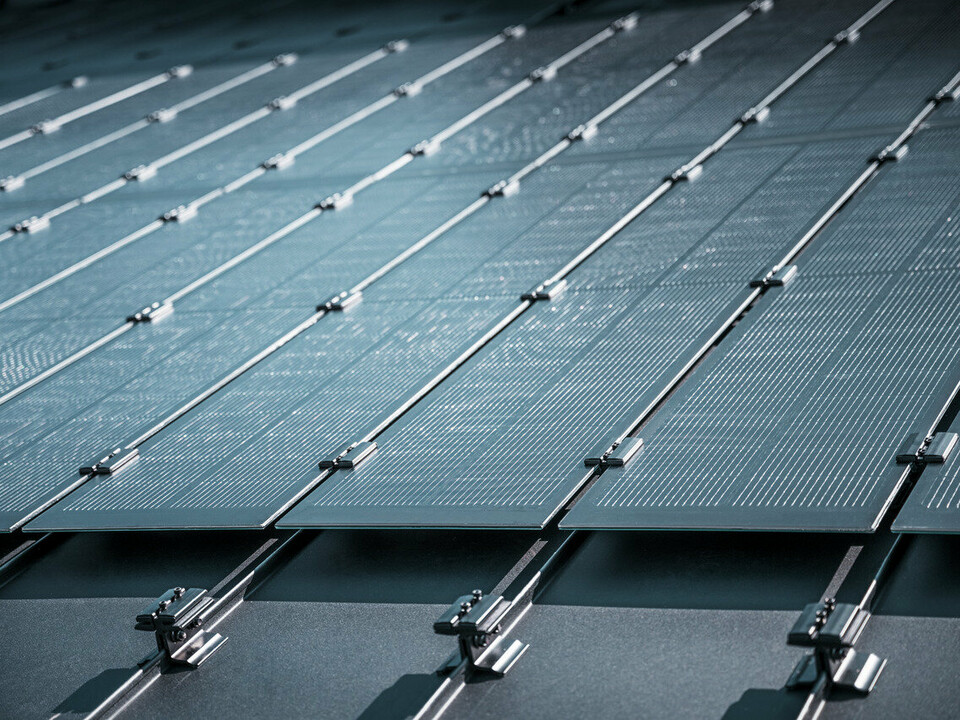

In principle, it’s not the material used, but rather the distance of a building from the point of origin of the lightning that influences its striking point. Therefore, the likelihood of a PREFA roof being struck by lightning is no greater than for any other roof or wall covering.

What’s more with PREFA small format components and with Falzonal and Prefalz coverings, there is an added advantage. These components can safely absorb and dissipate lightning currents produced during a lightning strike.

According to the standard ÖVE/ÖNORM EN 62305-3, metal roofs are a “natural” component of an arresting device. The suitability of PREFA roofing elements as a natural component of the lightning protection system (class H) has also been confirmed by external expert studies. Consequently, PREFA products contribute significantly to the building’s safety.

Preconception no. 3: “Aluminium is harmful to health.” — We say there’s nothing to worry about!

As a metal, aluminium is not harmful to human health. No adverse effects for the environment or water have ever been reported either.

Metallic aluminium is used in the building sector and the automotive industry, for aircraft construction, the manufacture of electrical devices and also for packing goods and food stuffs or as beverage cans. There are also aluminium compounds, created artificially in chemical processes, which differ from metallic aluminium. For instance, medicines, cosmetics or foodstuffs can contain aluminium hydroxide or aluminium chloride. Various media articles have warned about alleged health risks in this area, however no scientific evidence exists to prove this.

Preconception no. 4: “Aluminium is not an environmentally-friendly material.” — You’re kidding?

Aluminium can be fully recycled an infinite number of times — without any loss in quality. In aluminium production throughout the world, roughly a third of secondary aluminium, i.e. recycled aluminium, is used. In the building sector, as much as 90% of aluminium products are recycled after use. And the best part is: the manufacture of secondary aluminium only requires 5% of the energy required to obtain primary aluminium.

So you could say that aluminium is not consumed but utilised and repeatedly utilised again and again. So it’s highly likely that your PREFA roof was once an aluminium wheel on a Maserati or part of a garden fence for years, or perhaps both.

You see, there is much more to this excellent material, aluminium, than you first thought. And as is often the case, the preconceptions are completely groundless. Please contact us if you have any other questions. The PREFA team of experts will be delighted to hear from you.