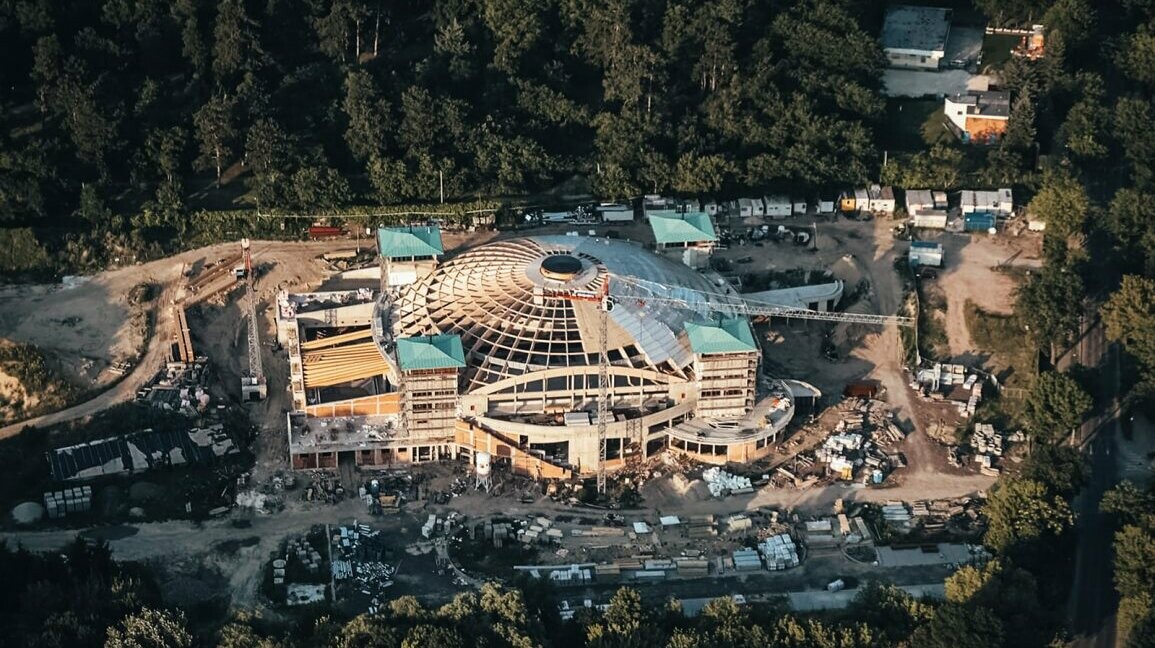

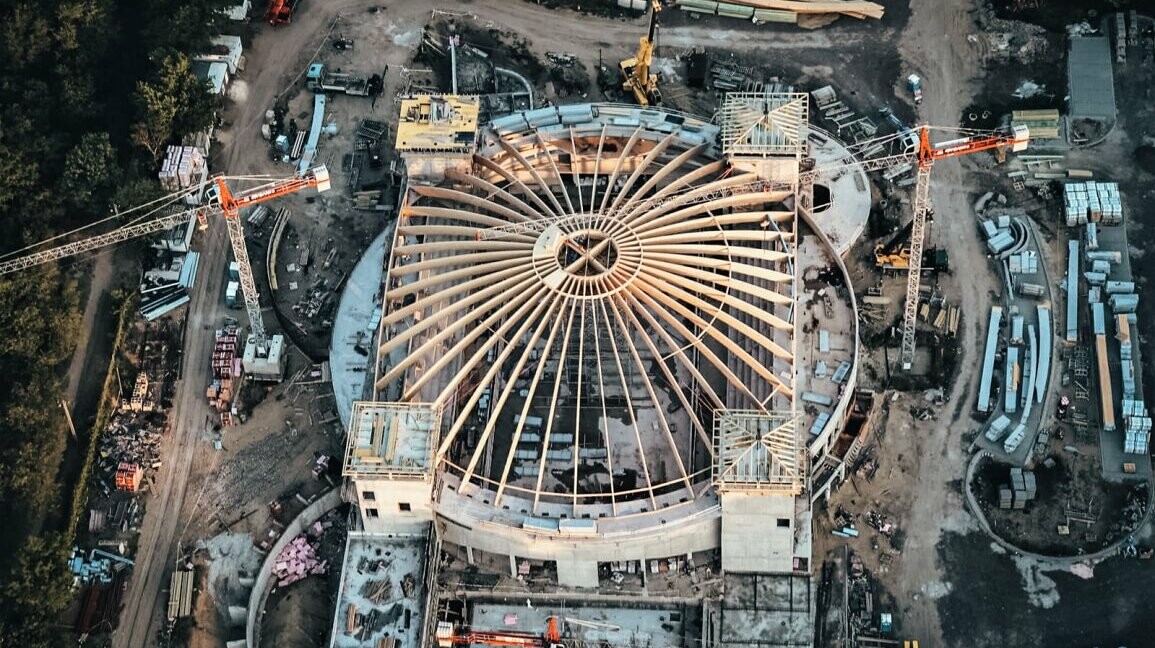

Its cupola, which will span the competition pool at a height of 26 meters, will be the biggest laminated cupola in Hungary. The tinsmith company Lemezfedés Ltd. has accepted the challenge to tile the 3600 m2 roofsurface of the cupola with Prefalz. PREFARENZEN visited the construction site and will accompany the project until the finish line.

One of the architectural gems of the city of Gödöllő with its 30.000 inhabitants is clearly the favourite castle of the Austro-Hungarian Empress Sisi. Not far from this tourist magnet, a modern swimming arena is being built with a historic abundance of form and shape. Although it will not be able to compete with Sisi’s castle from a tourist perspective, its roof requires remarkable planning performances. The planning of the Gödöllő project started in 2012, its construction began in late 2016 and it will be completed by the end of this year.

The right dimension

In Hungary, water sports are part of everyday life. Swimming lessons are compulsory in Hungarian schools, which may explain why Hungary’s water polo teams regularly win world and European championships. In the future, teams will also be able to train in Gödöllő. The swimming arena will clearly fulfil an important cultural and social function for urban life in the city of Gödöllő, which explains the respective dimension of the project: 7800 m2 of floor space cover 10 floors above and below ground. The basement floor reaches down to a depth of 8 meters, while the cupola’s vertex is 26 meters high. In addition to a competition pool, a warm-up pool and a sports pool for polo teams, the stadium will include a wellness area, fitness rooms and rooms for services. The main grandstand will accommodate up to 600 spectators. In addition, the swimming stadium is embedded in a park that should become an inner-city recreational area.

Think like a tinsmith

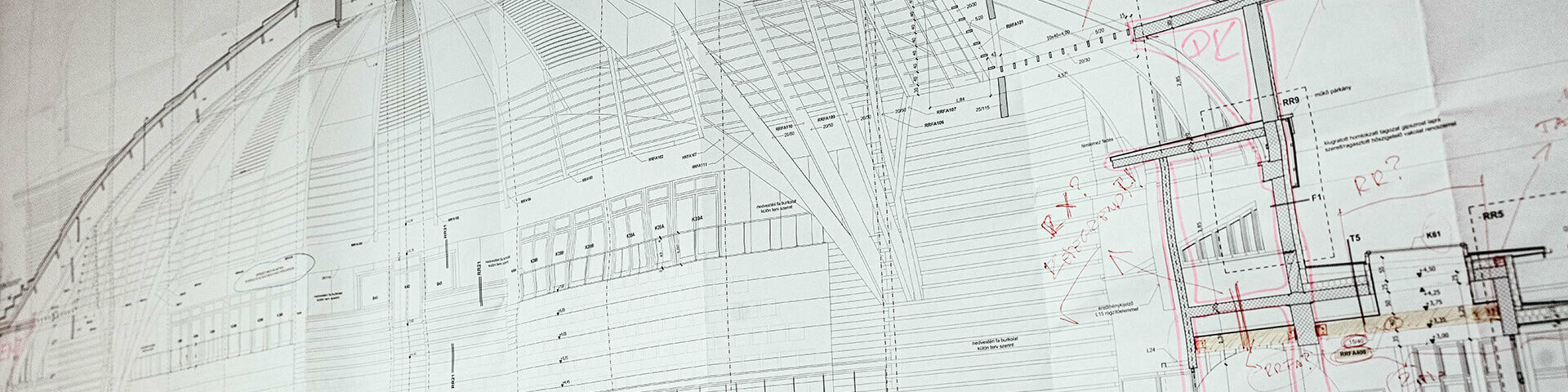

The construction with a central cupola and four towers requires specialist services particularly by the appointed tinsmiths. More than 4600 m2 of roof surface are covered with Prefalz Patina Green, of which 3600 m2 willprotect Hungary’s largest cupola-shaped laminated beam construction against weather-related damage in the future. While 20 carpenters are putting the finishing touches to the woodwork of the blind formwork for the base of the roofing on the large cupola, János Jánosa and András Valastyán, the founders of the tinsmith company Lemezfedés Ltd., are working on one of the corner towers. The view of the arched roof surface of the cupola from one of these towers almost takes your breath away. In the end, the roof should look like “a stone that drops into the water and creates circles” in line with the idea of the architect and Ybl Prize winner Jánosi János, partner at KVADRUM Architekten. To reach this goal, you need an innovative spirit, the courage to find constructive special solutions, patience and a tinsmith company that thinks ahead. “There aren’t many architects who think like a tinsmith,” as János Jánosa states. He appreciates the freedom in planning and the trust that was placed in them as tinsmiths in this project.

Green, distinctive, concentric

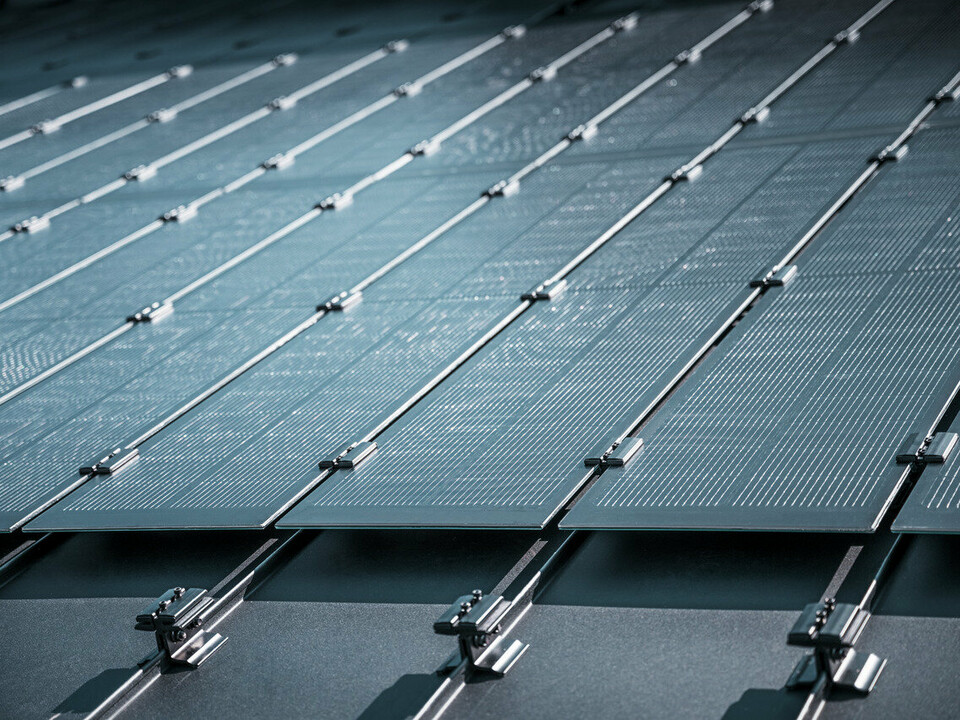

The cupola does not have the distinctive green aluminium cover yet. There is no chance to start with tinsmith work before the shell construction, the isolation and the sheathing have been completed. In order to limit the efforts and costs, tapered elements will not be laid. Instead, the experienced tinsmiths want to recreate the cupola vault with circularly arranged segment surfaces to create the impression that the material is concentrically spreading across a central glass eye. For this purpose, steps with a depth of 2.75 m are created in the underlying wood cover, which makes it possible to securely lay Prefalz.

Profiling machine at the construction site

The profiling machine provided by PREFA is used right at the construction site in Gödöllő. If necessary, PREFA Hungary provides profiling machines. However, the on-site folding work on the cupola roof in Gödöllő is an experiment. The profiling machine is lifted onto the cupola roof with a crane to come as close as possible to the place where the material needs to be processed. This facilitates work at the large construction site and significantly shortens workflows on the roof surface. It also means that folding corrections and adaptions can be made directly. András Valastyán joked that “thanks to PREFA, we could work at the site day and night.” He also mentioned the advantages of using Prefalz for this roof dimension: “Very light, easily workable, doesn’t break and doesn’t have to be warmed up at an outdoor temperature below 5 °C like other materials before it is processed at the construction site.”

Top tinsmiths

With their previous work, the tinsmiths involved in this project are clearly European champions. János and András have already processed material to a fold distance of 1 cm in the dizzying height of a church tower. There is not a single filigree roof covering in Europe that resembles that of the Holy Spirit Church in Veresegyház. And according to András, Lemezfedés Ltd. are the only tinsmiths in the world who can work with this high level of craftsmanship. Yet, they deliberately avoid global competition as long as they can find work in Hungary. They seem to have solved most of the technical challenges they have encountered so far. “Although,” as János Jánosa admits, “it would be a dream to realise three cupolas in this dimension simultaneously in the future, with more employees.”

Will they go for a swim in the swimming stadium when everything is finished? “Of course we’ll go swimming with a clear conscience,” both of them confirmed. After all, they were the ones who made the roof.

PREFARENZEN will stay on the ball with this project and report on future developments.

Swimming stadium Gödöllő - details

Country: |

Hungary |

Building, location: |

swimming stadium, Gödöllő |

Category: |

new construction |

Architecture: |

KVADRUM Architects |

Installer: |

Lemezfedés Kft. |

Material: |

|

Colour: |

P.10 patina green |

Further information

- Text & Interview: Claudia Gerhäusser

- Photos: Croce und WIR, Tardy Tamás Légifotó